Alternative Fuel

Overview

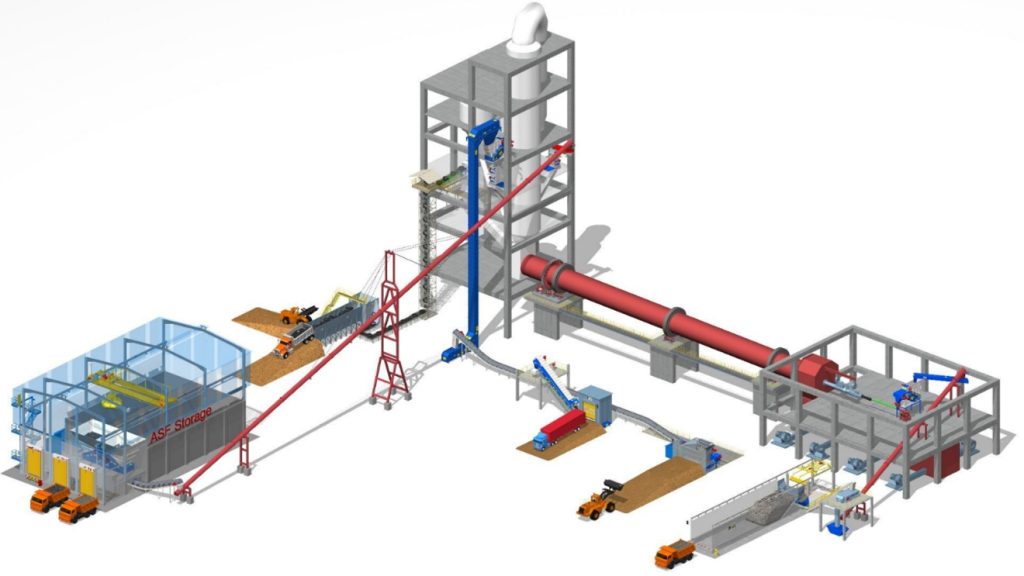

CETEC offers proven systems for converting municipal and industrial waste into alternative fuel for cement kilns. Our solutions help cement producers reduce fuel costs, meet environmental regulations, and improve carbon performance. From pre-processing to dosing and injection, we deliver end-to-end systems tailored for RDF, biomass, sewage sludge, and more.

Key Features

Lower Fuel Cost per Ton of Clinker

NOx & CO₂ Reduction with Certified Control

Compatible with RDF, Biomass, Sludge & TDF

Up to 70% Fuel Substitution Rate

Applications

Cement kilns seeking to cut fossil fuel use

Municipal solid waste conversion projects

Co-processing of sewage sludge, biomass, and industrial waste

Plants aiming for ESG compliance and carbon neutrality targets

Alternative Fuel

CETEC provides complete alternative fuel systems covering waste receiving, shredding, storage, dosing, and kiln injection. With successful installations across Asia and Africa, we help clients meet emission goals, reduce fossil dependency, and improve ESG scores — all while lowering fuel cost per ton of clinker.

Support & Services

AF assessment, chemistry & kiln impact analysis

Design, fabrication & installation of full AF system (storage, dosing, injection)

Operator training, SOPs & emission performance tuning