Product : P84 Polyimide needle felt filter bag

Application : Applied for kiln /raw mill and grate cooler dust collection of cement production line with capacity from 1000 to 12000tpd

Working condition : High temperature

Apply temperature : ≤240℃,peak value: 260℃

Dust content inlet : ≤1500 g/m³

Performance : ≤10 mg/Nm³

Warranty : 3 years

Contract : EP/EPC

Delivery : Sea/air/inland transportation

Payment terms : T/T, L/C & Others

Working temperature(℃):240

Peak temperature(℃):260

Dust content(g/m³):200、500、1000、1300、1500

Diameter(mm):115、120、125、130、145、150、155、160

Length(mm):2000、2450、3000、3200、3800、4800、6000、7000、8000

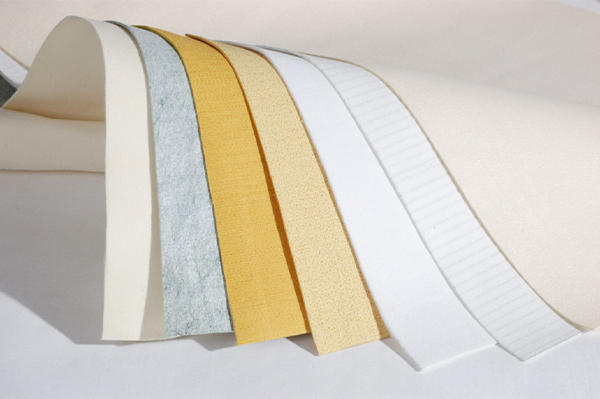

| Specification | Data |

| Material | P84 Fiber |

| Weight | 550 g/m² |

| Thickness | 2.0-2.2mm |

| Mechanical treatment | Heat setting, singe and calendaring |

| Chemical treatment | PTFE impregnating |

| Air permeability | 10-15 m²/m³/min |

| Break strength | Warp: ≥900 N/5cm Weft: ≥1200 N/5cm |

| Break elongation | Warp:≤35% Weft: ≤50% |

| Working temperature | ≤240℃ |

| Peak temperature | 260℃ |

| Anti-acid | Excellent |

| Anti-alkali | Excellent |

| Anti-oxidation | Good |

| Anti-abrasion | Moderate |

| Resistance to hydrolysis | Good |

Carding short fibers to open completely

Overlapping net with good continuity

Proper depth of pre needling to avoid damaging the strength

The felt has good adhesion after main thorn and shaving

The corrosion resistance of the fabric can be improved by chemical impregnation, extrusion, de-hydration, drying, sintering and treatment

Stretching and setting is the guarantee the quality of filter material

Reasonable control of high temperature hot rolling and setting temperature

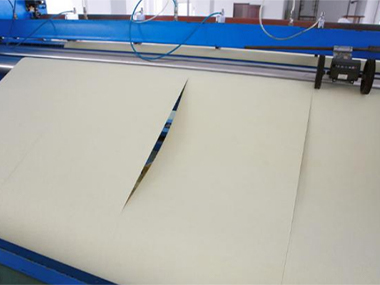

The slitter automatically cuts off, neat, stable size, no deviation

The slitter is used to cut, which provides the premise guarantee for the stability of bag size

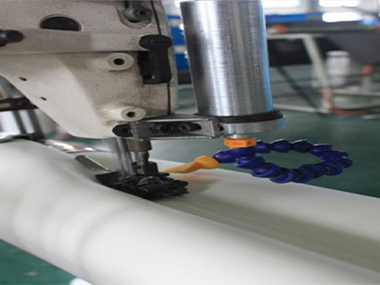

Strictly confirm to Sewing standard

Sewing needle distance. within 100mm±2

Suture width: 22- 25mm.

Inner diameter deviation: ±1mm

High quality high temperature resistant, corrosion-resistant and high strength sewing thread is selected for middle three stitch

Any Question Concerning Our Services.Contact Us Now.

Any Question Concerning Our Services.Contact Us Now.